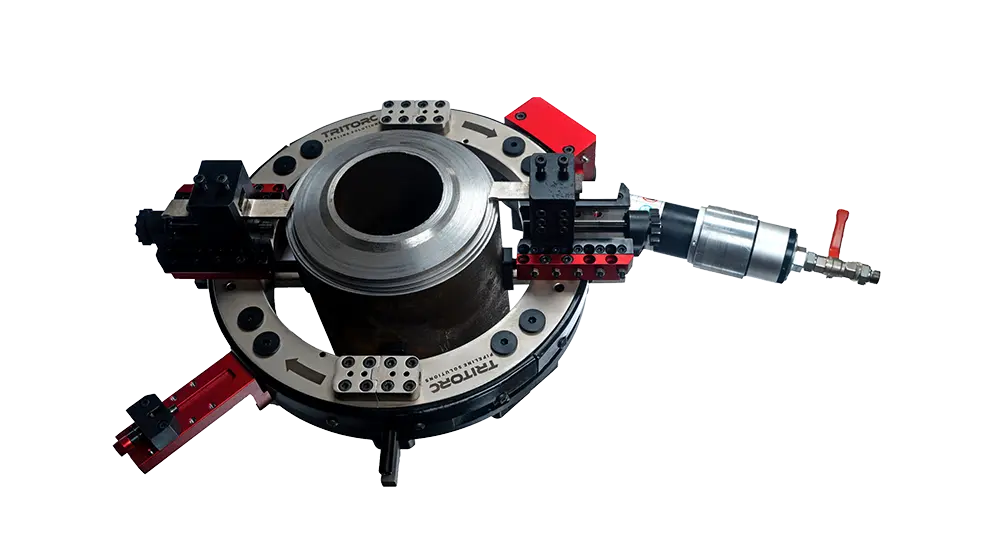

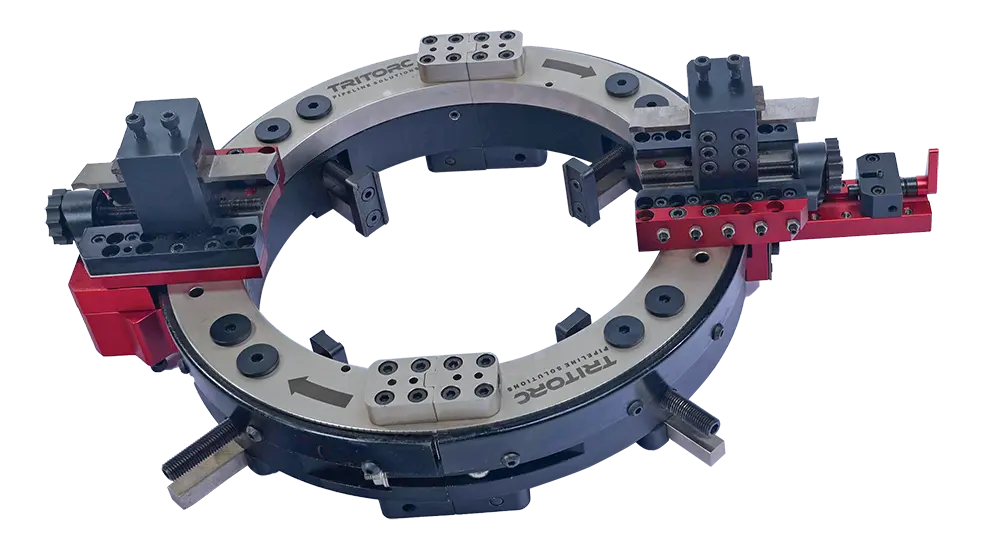

Pipe Cutting Machine – TSF Series

The TSF Series is a specialized, split-frame pipe cutting and beveling machine engineered for manufacturers and industrial operators. Its spark-free technology ensures safe, precise operations in hazardous environments. Featuring multiple tool slides and adjustable motor positions, it delivers efficient, accurate pipe preparation, even in confined spaces.

The TSF Series is an innovative pipe cutting and beveling machine that provides precise and efficient results for all types of pipe cutting, beveling, and end preparation. The innovative split frame design allows easy assembly and disassembly, which makes the operations easy.. This spark-free cutting technology is perfect for working in environments where sparks/heat generation is to be avoided. The TSF Series ensures fast and accurate cutting and beveling, even in confined spaces. It also has various tool slides and multiple motor positioning options.

Overview

Tritorc’s TSF Series is a robust, split-frame solution tailored for manufacturers and heavy industries such as oil & gas, petrochemical, and construction. Designed for secure OD mounting, it enables simultaneous, spark-free pipe cutting and beveling in restricted areas. Supporting various bevel profiles and automatic feed, TSF models accommodate pipes from 2″ to 72″, providing specialized, high-precision performance for demanding industrial applications.

Technical Specification

| Model No | Range | Machine ID | Machine OD | Thickness | Height | Weight |

|---|---|---|---|---|---|---|

| inch | mm | mm | mm | mm | kg | |

| TSF-6 | 2-6 | 184 | 324 | 70 | 80 | 38.3 |

| TSF-8 | 2-8 | 238 | 378 | 70 | 80 | 40.5 |

| TSF-10 | 4-10 | 292 | 432 | 70 | 80 | 49 |

| TSF-12 | 6-12 | 343 | 483 | 70 | 80 | 55.8 |

| TSF-14 | 8-14 | 373 | 513 | 70 | 80 | 57 |

| TSF-16 | 10-16 | 422 | 562 | 70 | 80 | 60.8 |

| TSF-18 | 12-18 | 482 | 622 | 70 | 80 | 64.2 |

| TSF-20 | 14-20 | 526 | 666 | 70 | 80 | 68.9 |

| TSF-22 | 16-22 | 578 | 718 | 70 | 80 | 70.1 |

| TSF-24 | 18-24 | 34 | 774 | 70 | 80 | 77.3 |

| TSF-28 | 22-28 | 739 | 923 | 92 | 83 | 128.7 |

| TSF-30 | 24-30 | 799 | 983 | 92 | 83 | 134.8 |

| TSF-36 | 30-36 | 958 | 1142 | 92 | 83 | 147.3 |

| TSF-42 | 36-42 | 1108 | 1292 | 92 | 83 | 166.5 |

| TSF-48 | 42-48 | 1258 | 1442 | 92 | 83 | 180 |

| TSF-56 | 48-56 | 1473 | 1657 | 92 | 83 | 185 |

| TSF-60 | 54-60 | 1573 | 1763 | 95 | 94 | 211 |

| TSF-66 | 60-66 | 1729 | 1916 | 93.5 | 94 | 224 |

| TSF-72 | 66-72 | 1867 | 2054 | 93.5 | 94 | 237.3 |

Frequently Asked Questions

What pipe sizes can the TSF Series accommodate?

The TSF Series can accommodate pipes ranging from 2″ to 72″ in diameter, depending on the model.

What is the power requirement for the TSF Series?

Can the TSF Series be used for both cutting and beveling simultaneously?

What bevel types can the TSF Series produce?

Is the TSF Series suitable for heavy-wall pipes?

How easy is it to transport the TSF Series for on-site jobs?

Does Tritorc provide service and support for TSF Series equipment?