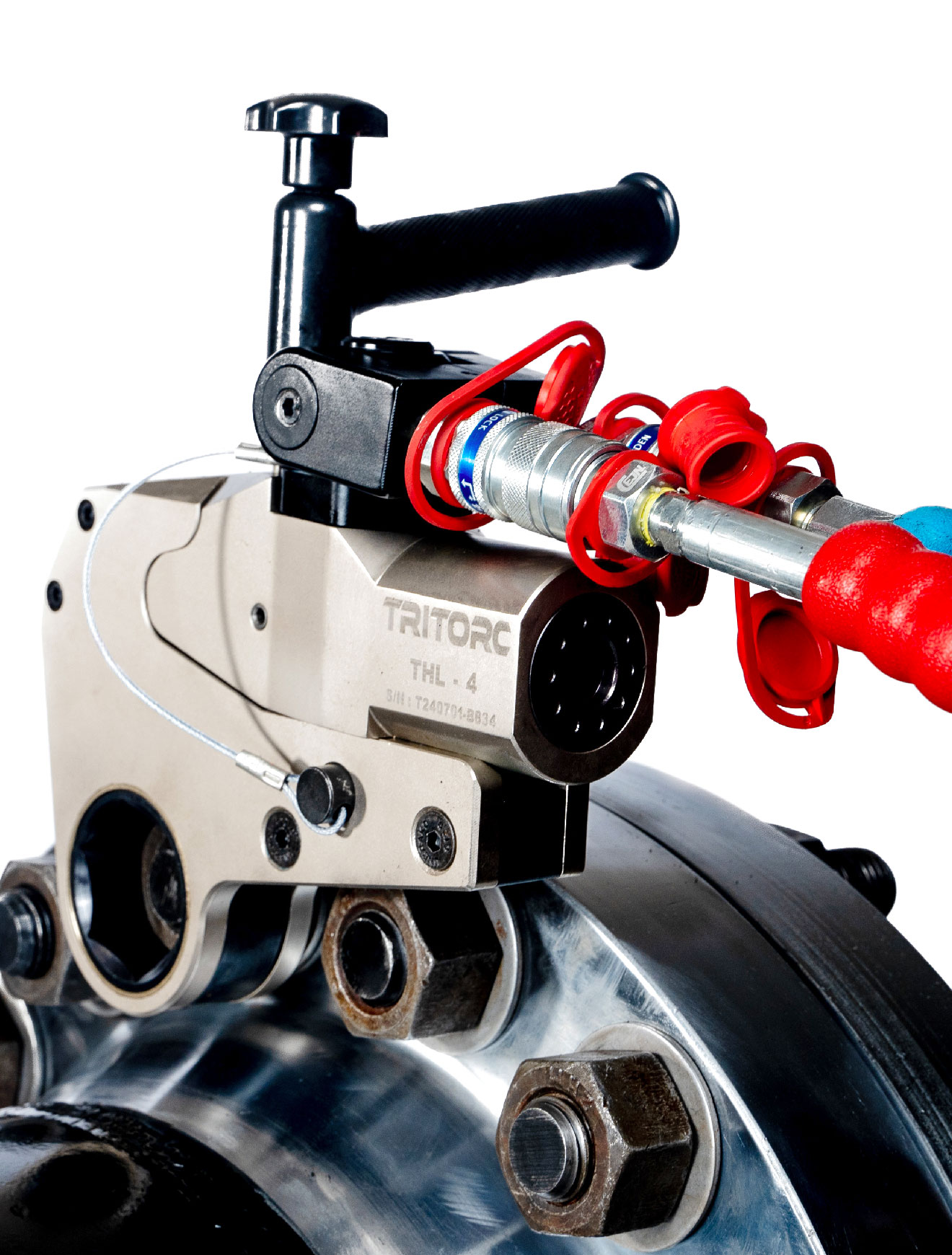

Low Profile Ratchet Type – THL Series

Bolting in confined spaces demands precision, strength, and repeatability. The THL Series Low-Profile Ratchet Torque Wrench is engineered for critical bolting operations where access is limited. Built for reliability under pressure, it ensures accurate torque delivery without compromising safety or productivity in shutdowns or live systems.

The TSL Series Square Drive Hydraulic Torque Wrench delivers accurate, repeatable torque for heavy-duty bolting in global industrial sectors. Designed for reliability and strength, it handles diverse applications in wind turbines, mining, and infrastructure, ensuring consistent torque performance under high-load and high-pressure conditions.

Overview

The THL Series is a compact hydraulic torque wrench built for challenging bolting jobs in restricted access zones across Oil & Gas, Power, and Petrochemical industries. Its low-profile design, robust ratchet mechanism, and high-strength alloy construction make it ideal for flange joints, heat exchangers, and heavy machinery. When every bolt matters and downtime isn’t an option, the THL Series delivers power, precision, and trusted performance.

Technical Specification

| Technical Data | Units | THL-2 | THL-4 | THL-8 | THL-14 | THL-32 | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Min. Torque | Nm (Ft. Lbs.) | 273 (201) | 315 (232) | 578 (426) | 677 (499) | 1228 (906) | 1508 (1112) | 2168 (1599) | 2402 (1772) | 4919 (3628) | 5191 (3829) |

| Max. Torque | Nm (Ft. Lbs.) | 2728 (2012) | 3008 (2219) | 5781 (4264) | 6733 (4966) | 12281 (9058) | 15078 (11121) | 21675 (15987) | 24022 (17718) | 49192 (36282) | 51909 (38286) |

| Across Flat | mm (Inch) | 19-48 (3/4 – 1.7/8) | 49-60 (1.15/16 – 2.3/8) | 33-56 (1.5/16 – 2.3/16) | 57-80 (2.1/4 – 3.1/8) | 41-80 (1.5/8 – 3.1/8) | 81-105 (3.3/16 – 4.1/8) | 50-99 (2 – 3.7/8) | 100-120 (3.15/16 – 4.3/4) | 90-145 (3.7/8 – 5.11/16) | 146-175 (5.3/4 – 6.7/8) |

| Drive Unit Weight | Kg. (Lbs.) | 1.5 (3.3) | 1.5 (3.3) | 3.2 (7.1) | 3.2 (7.1) | 5.3 (11.7) | 5.3 (11.7) | 9.8 (21.6) | 9.8 (21.6) | 15 (33.1) | 15 (33.1) |

| Ratchet Unit Weight | Kg. (Lbs.) | 1.7 (3.7) | 1.85 (4.1) | 4.1 (9.0) | 4.2 (9.3) | 8.7 (19.2) | 8.8 (19.4) | 11.5 (25.4) | 15.5 (34.2) | 32 (70.6) | 35 (77.2) |

| Dimensional Data | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Units | THL-2 | THL-4 | THL-8 | THL-14 | THL-32 | |||||||

| Overall Length L | mm (inch) | 164 (6.46) | 169 (6.65) | 202 (7.95) | 218 (8.58) | 267 (10.51) | 285 (11.22) | 325 (12.80) | 329 (12.95) | 408 (16.06) | 443 (17.44) | |

| H1 | mm (inch) | 132 (5.20) | 143 (5.63) | 168 (6.61) | 184 (7.24) | 198 (7.80) | 223 (8.78) | 237 (9.33) | 251 (9.88) | 299 (11.77) | 321 (12.64) | |

| H2 | mm (inch) | 99 (3.90) | 110 (4.33) | 129 (5.08) | 144 (5.67) | 159 (6.26) | 184 (7.24) | 193 (7.60) | 209 (8.23) | 259 (10.20) | 281 (11.06) | |

| W1 | mm (inch) | 32.2 (1.27) | 32.2 (1.27) | 40.6 (1.60) | 40.6 (1.60) | 52.5 (2.07) | 52.5 (2.07) | 63 (2.48) | 63 (2.48) | 83 (3.27) | 83 (3.27) | |

| W2 | mm (inch) | 34.4 (1.35) | 34.4 (1.35) | 49.5 (1.95) | 49.5 (1.95) | 61.5 (2.42) | 61.5 (2.42) | 81 (3.19) | 81 (3.19) | 93 (3.66) | 93 (3.66) | |

| Nose Radius R | mm (inch) | 22-43 (0.87-1.69) | 43-46 (1.69-1.81) | 33-46 (1.30-1.81) | 46-60 (1.81-2.36) | 42-63 (1.65-2.48) | 63-81 (2.48-3.19) | 53-80 (2.09-3.15) | 80-92 (3.15-3.62) | 90-114 (3.54-4.49) | 114-128 (4.49-5.04) | |

| R min | mm (inch) | 9.5 (0.37) | 10 (0.39) | 10 (0.39) | 13 (0.51) | 12 (0.47) | 20 (0.79) | 17 (0.67) | 22 (0.87) | 25 (0.98) | 25 (0.98) | |

| R max | mm (inch) | 14.5 (0.57) | 15.5 (0.61) | 15 (0.59) | 18 (0.71) | 20 (0.79) | 24 (0.94) | 27 (1.06) | 29 (1.14) | 31 (1.22) | 31 (1.22) | |

Frequently Asked Questions

What industries is the THL Series best suited for?

The THL Series is ideal for industries requiring precision bolting in confined spaces, such as oil & gas, petrochemical, power generation, and heavy machinery.

What torque accuracy can I expect from the THL Series?

Are the ratchet links interchangeable for different bolt sizes?

What materials are used in the construction of the THL Series?

Can the THL Series handle high-pressure environments?

Does the tool offer flexibility in hose connection?

How does the THL Series help reduce operator fatigue?

Is the THL Series corrosion-resistant?